If you want to know how to lower spare tire without tool, you’re at the right place. This guide contains everything you need to know to complete the task. The step by step instructions given below doesn’t leave any room for confusion or mistake.

They are also easy to follow and practical. You don’t have to be a mechanic to put them to practice. Anyone who has ever held a tool in their life can use them to get their vehicle back on the road in little to no time. That isn’t where the good news end.

Our experts prepared these directives with the assumption that anyone using them would be on their own. That there might not be anyone assisting them in lowering their spare tire. It’s a good thing if you ask us as it means you can complete the task without any help.

Before you lower spare tire without tool

Here’s what you need to do:

Make sure your vehicle does have a spare tire

Before you go about reading our instructions, it’s important to make sure that you indeed have a spare tire in your vehicle. Most people assume this scenario without ever bothering to verify their assumption by looking at the spare tire. Such persons are often left with nothing at the end.

To verify the presence of the spare tire, discard the rectangular plastic cover under the passenger side of your vehicle’s license plate. If you can see an entrance for a key beneath the plastic cover, then you can be sure that your car does indeed has its spare tire.

Get the necessary supplies

That you’re going to lower the spare tire without ‘tool’ doesn’t mean you are going to go about the task with bare hands. Doing that would be counterproductive. You will still need some supplies to compensate for the lack of the key. Here’s what you’ll need.

Purchase a jack kit (without the jack). You can buy one from your local hardware store or Amazon. The next item on your ‘to-get’ list is an ignition key. Alongside the components of the Jack kit, the ignition key will loosen the tire’s connection with the wheel.

Park the vehicle on a stable, flat surface

Experts tell us that one should never change tires on a slope. The same advice is applicable when you’re lowering a spare tire. Vehicles parked on an incline are extremely likely to go backward, thereby putting the safety of the person under the vehicle at risk.

Once you’ve done that, apply the hand brake. Turn on the emergency lights if you’re on the roadside. Put your vehicle in gear (if manual) or in parking (if automatic). Make sure that no one is sitting inside the car and put chocks or similar heavy objects behind all the wheels.

How to lower spare tire without a tool

Follow these instructions to lower spare tire without a tool:

What you’ll need?

- Ignition Key

- Jack Kit

Step-by-Step Guide

Step 1: Slide underneath the bumper

Picture in your mind the exact location of the spare tire. Or you can just fall to your knees and look beneath the vehicle. Fixate your attention to the back of the vehicle. There you’ll see a bulge protruding downwards. That is the spare tire that you’re going to lower.

The exact location of the spare tire will be just behind the tow hitch bar and under the bumper. You can further verify that the bulge is a spare tire by pressing your hand against it. The tire’s trenches will let you know that it’s indeed what you’re looking for.

Step 2: Insert the ignition key

Insert the ignition key in the hole beneath the plastic cover you discarded earlier. Drag the key towards you and you’ll end up detaching it from the hole. Doing this is vital as it will allow you to fix the assembly at the rear of your vehicle.

Step 3: Open the Jack kit

Get the crowbar and a couple of rods. One of the roads will have a wider end. Mechanics usually call this end the ‘female’ end. You’re going to insert this end of the rod into the hole that you disclosed in the previous step with the ignition key.

Step 4: Fit the 2nd rod to the female end rod

Doing this will help you in two ways. It will provide you enough space to add the male end of the pulley to the female rod. You will also be left with enough space to remove the bumper.

Look closely to make sure that the fitment between the female end rod and the 2nd rod is perfect. Then put this end through the hole.

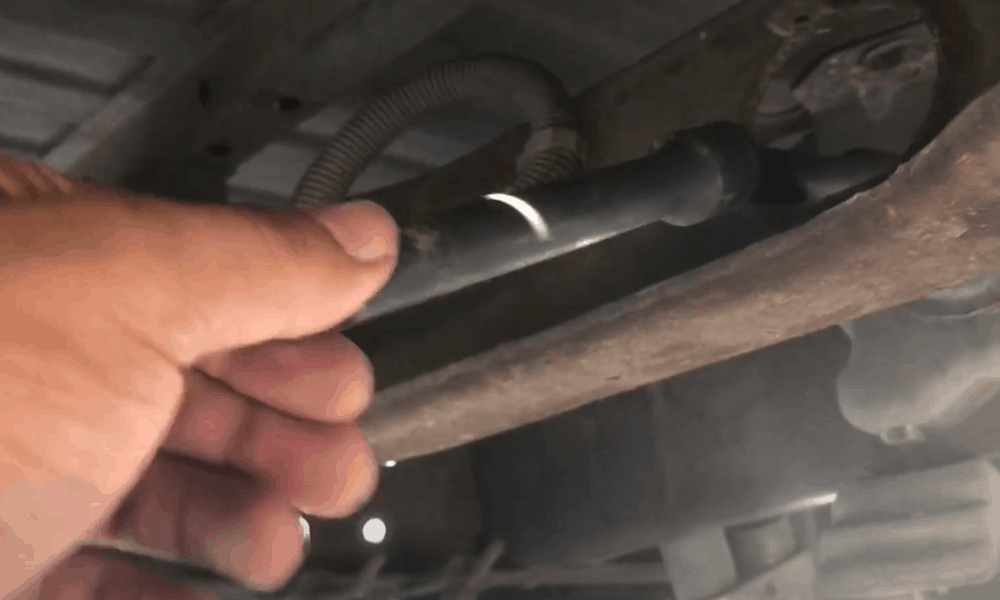

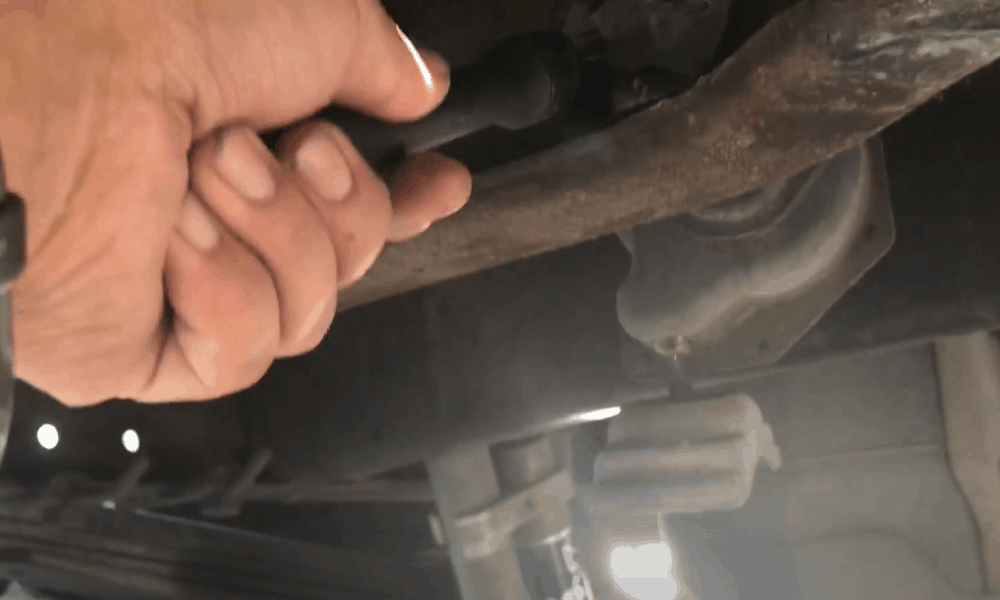

Step 5: Fit the crowbar to the other end

You have by now one end of the rod into the hole. The other end, which is staying out of the bumper, should now be added to the crowbar. Follow that up by turning the crowbar in an anti-clockwise direction.

This will allow you to swivel the pulley and, by extension, the spare tire to the ground. Keep on rotating as long as the spare tire isn’t entirely on the floor.

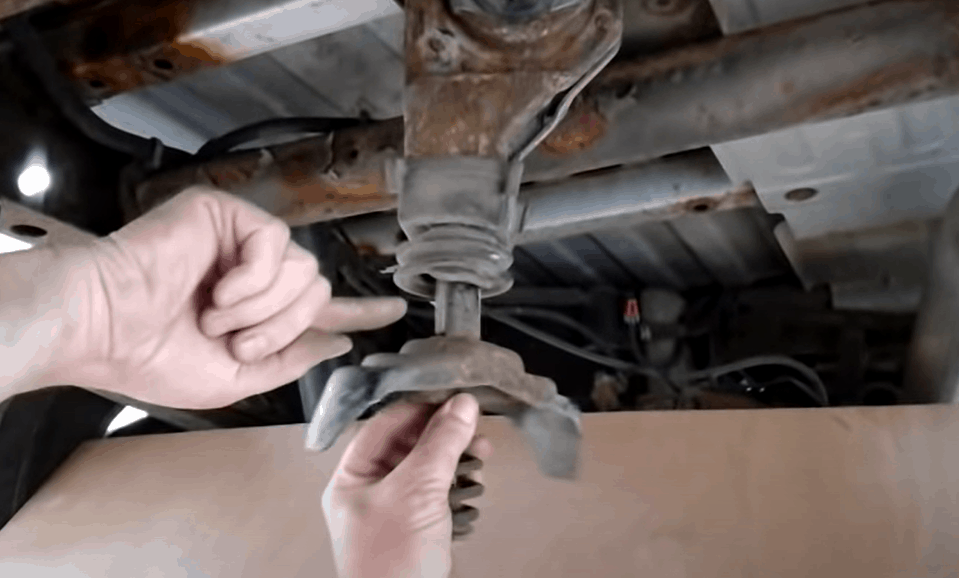

Final Step: Distinguish the rim from the pulley carrier

This will let you detach the tire from below the vehicle. Keep one hand on the tire and the other on the middle gap of the rim. Apply full force to pull both ends apart and off the peak.

Conclusion

Lowering a spare tire without a tool isn’t exactly straightforward. You have to apply a lot of effort and the whole process will take about an hour for an amateur. Yet it is better than the alternative, which is to wait for hours on the roadside for help. You should therefore be aware of how to accomplish this task.

The post 6 Steps to lower spare tire without tool appeared first on Smart Motorist.

source https://www.smartmotorist.com/how-to-lower-spare-tire-without-tool